Polyurethane Resin

Polyurethanes are versatile materials that can be tailored for many different applications. A wide variety of hardness, cure speeds, viscosities, mechanical and thermal properties are possible. Alchemie manufacture an extensive range of two component polyurethane systems for applications such as vacuum casting, RIM casting, clear casting, model making and tooling.

-

PU3675

ALCHEMIX PU 3675 is a low viscosity, two component polyurethane system which can be used to produce patterns, moulds, models and prototypes with excellent fine detail replication. ALCHEMIX PU 3675 can be filled with mineral or metallic fillers for reduced shrinkage, and has rapid demould times even when cast in thin sections. Learn More -

PU3676

ALCHEMIX PU 3676 is a low viscosity, two component polyurethane system which can be used to produce patterns, moulds, models and prototypes with excellent fine detail replication. ALCHEMIX PU 3676 can be filled with mineral or metallic fillers for reduced shrinkage, and has rapid demould times even when cast in thin sections. Learn More -

PU368

ALCHEMIX PU368 is a two component, odourless fastcast polyurethane system to which specific dry fillers can be added. The high flexural strength of this product ensures that parts with thin sections are very strong and not brittle. Extremely high Tg ensures thermal stability at high temperature. Very low and time stable shrinkage. Learn More -

PU3684

ALCHEMIX PU 3684 is a fast curing polyurethane casting system designed for applications requiring parts with high stiffness. The low colour of the system allows for easy pigmentation. ALCHEMIX PU 3684 can be filled with mineral or metallic fillers for reduced shrinkage. Learn More -

PU3685

ALCHEMIX PU 3685 is two component polyurethane system with a 25% renewable carbon content. The product can be used to produce patterns, moulds, models and prototypes with excellent fine detail replication. ALCHEMIX PU 3685 can be filled with mineral or metallic fillers for reduced shrinkage Learn More -

PU3691

ALCHEMIX PU 3691 is an unfilled, no odour, low viscosity two component polyurethane system to which specific dry fillers can be added in either the suggested or variable ratios depending on the application and the required thickness of the casting. Can be used to produce ultra-fine detail in model-making, or as a low viscosity casting resin for pattern-making. Learn More -

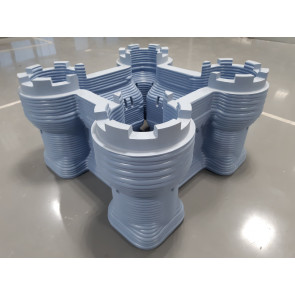

PU3720

ALCHEMIX PU 3720 is a machine-mixed polyurethane paste system that is particularly suitable for the manufacture of design / styling models, master models or parts requiring high strength combined with low density. The product is thixotropic and cures quickly, allowing the rapid build-up of layers and the printing of parts with overhanging sections. The cured material can be easily machined or worked with hand tools to give a smooth surface finish. Printing parts using ALCHEMIX PU 3720 gives a significant reduction in waste when compared to traditional methods. Learn More -

PU375

ALCHEMIX PU 375 is a two component, low odour, prefilled fastcast polyurethane system. It has excellent detail of reproduction, fast cure and demould time. The product has low shrinkage and good machinability. Learn More -

PU375S

ALCHEMIX PU 375S is a two component, low odour, prefilled fastcast polyurethane system. It has excellent detail of reproduction, fast cure and demould time. The product has low shrinkage and good machinability. The system has an extended pot life to allow for larger castings up to 50 Kg. Learn More -

PU376

ALCHEMIX PU 376 is a two component, low odour, prefilled fastcast polyurethane system. Prefilled with special metallic fillers. Easy processing and low viscosity prevents air entrapment. Extremely high Tg post cure ensures stability at high temperatures. It has a good surface finish and is easily polishable. Learn More