Mould Making

Products that are specifically designed and formulated for Mould Making.

-

UP8960

ALCHEMIX UP8960 is a two component polyester paste used for filling/repairing holes or imperfections in the surfaces of steel, aluminium or GRP tools. Learn More -

RTV256

ALCHEMIX RTV 256 is a two component addition cure silicone rubber. Used for the moulding of complicated parts with precise dimensions this oil bleed silicone is specially designed for long mould life and good release. Learn More -

RTV245

ALCHEMIX RTV 245 is a two component addition cure silicone rubber used for the moulding of complicated parts with precise dimensions, repetitive casting applications, ceramics, vacuum casting moulds and general mould making. Learn More -

RTV240

ALCHEMIX RTV 240 is a two component addition cure silicone rubber with the facility to alter the Shore A hardness by the use of different catalysts. Used for the moulding of complicated parts with precise dimensions. There is also a blue catalyst available for the product. Learn More -

RTV201

ALCHEMIX RTV 201 is a thixotropic agent to be used with ALCHEMIX RTV240. When added to the silicone mixture it will thicken the material depending on how much agent is added. Learn More -

RTV134

ALCHEMIX RTV 134 is a two-component condensation cure, low viscosity silicone rubber. Suitable for mould making, producing replicas of polyester, epoxy resins, urethane foam and wax etc. It can precisely reproduce the shape of the original model. ALCHEMIX RTV 134 has exceptionally high tear strength and good elongation. Learn More -

PU376

ALCHEMIX PU 376 is a two component, low odour, prefilled fastcast polyurethane system. Prefilled with special metallic fillers. Easy processing and low viscosity prevents air entrapment. Extremely high Tg post cure ensures stability at high temperatures. It has a good surface finish and is easily polishable. Learn More -

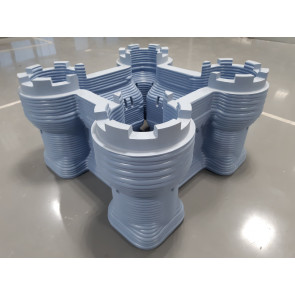

PU3720

ALCHEMIX PU 3720 is a machine-mixed polyurethane paste system that is particularly suitable for the manufacture of design / styling models, master models or parts requiring high strength combined with low density. The product is thixotropic and cures quickly, allowing the rapid build-up of layers and the printing of parts with overhanging sections. The cured material can be easily machined or worked with hand tools to give a smooth surface finish. Printing parts using ALCHEMIX PU 3720 gives a significant reduction in waste when compared to traditional methods. Learn More -

PU3676

ALCHEMIX PU 3676 is a low viscosity, two component polyurethane system which can be used to produce patterns, moulds, models and prototypes with excellent fine detail replication. ALCHEMIX PU 3676 can be filled with mineral or metallic fillers for reduced shrinkage, and has rapid demould times even when cast in thin sections. Learn More -

PU3675

ALCHEMIX PU 3675 is a low viscosity, two component polyurethane system which can be used to produce patterns, moulds, models and prototypes with excellent fine detail replication. ALCHEMIX PU 3675 can be filled with mineral or metallic fillers for reduced shrinkage, and has rapid demould times even when cast in thin sections. Learn More