Automotive industry chooses Alchemie to streamline concept car design

12/08/2014

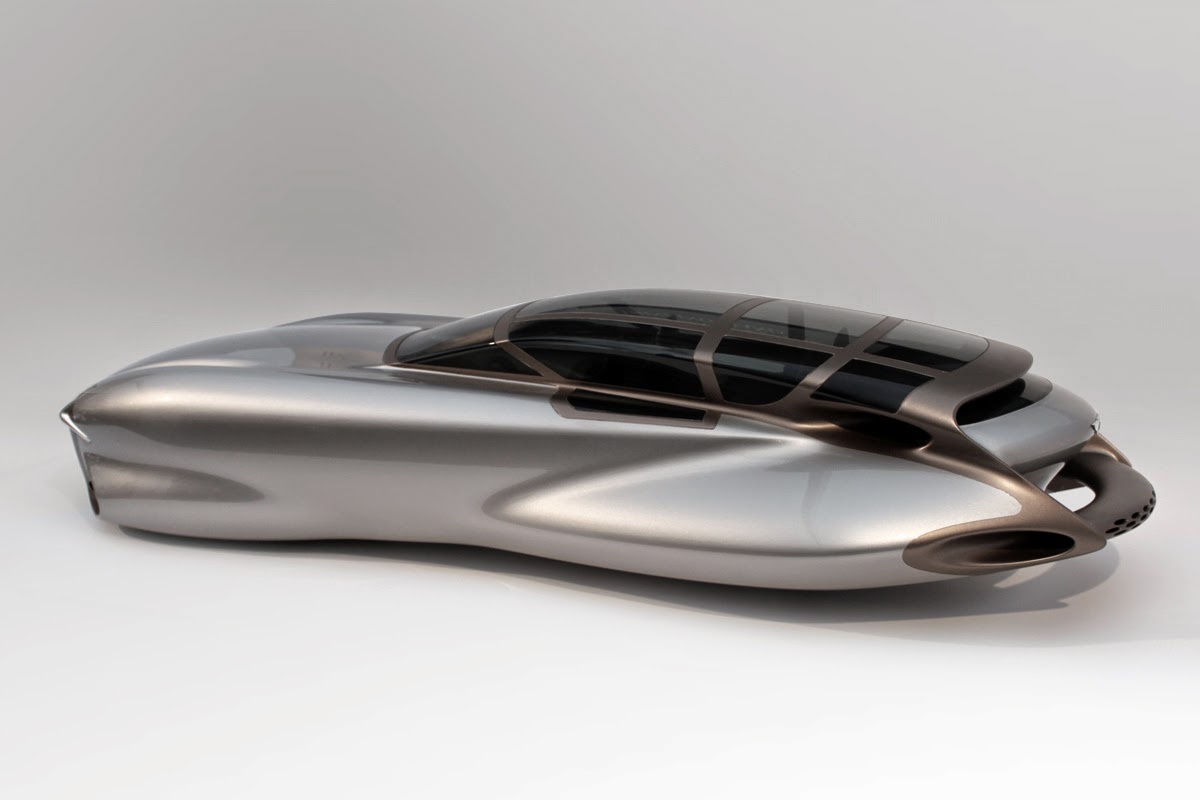

Prestigious car manufacturer Bentley have been approached by vehicle designer Hoe-young Hwang, to work in partnership to create an ultra-modern car. The aesthetically pleasing design came about due to the designer wanting to go back to traditional modelling methods, by hand crafting the car, and not relying on concepts completely created by CAD and 3D printing. Going back to conventional freehand drawing and creating a sheet metal model of the vehicle, allowed for smooth contours and a more streamlined effect.

To view the design process video for the vehicle, please click on the link below:-http://youtu.be/dnwHC4e0kpg

The Royal College of Arts designer contacted Alchemie to see if it was possible to develop an extremely light weight, crystal clear product, for the streamline roof of the vehicle, which would specifically fit the criteria. This required the material to be transparent, and also have the ability to withstand high speeds, while not sacrificing the rigid chemical structure. An extremely low density material was also key, to ensure that the weight of the vehicle was kept as low as possible.

Close consultation with the designer resulted in a vacuum casting material being the most suitable, specifically VC 3341. This is a UV stable, water clear polyurethane vacuum casting resin designed to simulate thermoplastics such polycarbonate, shock resistant PMMA and ABS. The material has excellent mechanical properties and extremely high heat distortion temperature. The system is specifically designed for use in gravity vacuum casting machines.

Due to the success of the design, the vehicle was recently showcased at the RCA Show 2014.

For more information on how Alchemie can resolve your material requirements please contact us direct on 01926 641600